Understanding Respiratory Protective Equipment (RPE) in the UK

Respiratory Protective Equipment (RPE) is a specific type of Personal Protective Equipment (PPE) designed to safeguard the wearer against inhaling hazardous substances present in the workplace air or from working in oxygen-deficient atmospheres. In the UK, the selection, use, and maintenance of RPE are primarily governed by the Control of Substances Hazardous to Health (COSHH) Regulations 2002 and enforced by the Health and Safety Executive (HSE). You can download the HSE publication HSG53: "Respiratory protective equipment at work: A practical guide" for free from their website.

RPE should only be considered when other control measures, such as eliminating the hazard or using local exhaust ventilation (LEV), are not reasonably practicable or sufficient to reduce exposure to an acceptable level. RPE is often viewed as the "last line of defence" in the hierarchy of control.

The Two Main Types of RPE

RPE is categorised into two main types based on their method of providing breathable air:

1. Respirators (Filtering Devices)

Respirators work by using filters to remove contaminants (like dust, mist, gas, or vapour) from the air before it is inhaled. They rely on the ambient air containing sufficient oxygen and must not be used in oxygen-deficient atmospheres.

Non-Powered Respirators

- Mechanism: Rely on the wearer's breathing to draw contaminated air through the filter. This creates a negative pressure inside the facepiece relative to the outside air.

- Filtering Facepieces (FFP Masks): These are often disposable half masks that filter particles. They are classified by their efficiency:

- FFP1: Low efficiency.

- FFP2: Medium efficiency.

- FFP3: High efficiency (often required for hazardous substances like asbestos or fine viral aerosols).

- Half Masks and Full-Face Masks: These are typically reusable and use replaceable filters for particles, gases, or both.

- Requirement: All tight-fitting non-powered respirators must be face fit tested to ensure a tight seal with the wearer's face, preventing leaks of contaminated air.

Powered Respirators (PAPR)

- Mechanism: A battery-powered motor draws air through a filter and then feeds the clean air into the facepiece, hood, or helmet at a positive pressure.

- Benefit: The positive pressure reduces the risk of contaminant leakage into the facepiece, even with minor gaps. This makes them suitable for people with facial hair or those who cannot achieve a good seal with a tight-fitting mask.

- Examples: Powered filtering facepieces, or air turbos feeding hoods, helmets, or visors. Some powered units require a fit test if they use a tight-fitting facepiece, but those with loose-fitting facepieces (e.g., hoods) generally do not.

2. Breathing Apparatus (BA)

Breathing Apparatus provides the wearer with a supply of breathing-quality air from an independent source, isolating them entirely from the ambient atmosphere.

Mechanism: Delivers clean air from a cylinder (Self-Contained Breathing Apparatus, or

SCBA) or an airline connected to a compressor (Air-fed Breathing Apparatus).

- Usage: Essential for environments where oxygen levels are, or may become, low (oxygen-deficient atmospheres), or where contaminant levels are very high, such as in confined spaces.

- Examples: SCBA for emergency entry or rescue, and airline breathing apparatus for prolonged work. These can also be fitted with tight-fitting or loose-fitting facepieces (e.g., full-face masks or hoods).

RPE Facepiece styles

The second major way RPE is classified is by the style of the facepiece:

1. Tight-fitting Facepieces (Masks)

- Function:

Rely on creating a secure, uninterrupted seal all around the edge of the facepiece to prevent contaminated air from leaking in.

- Examples:

Filtering Facepieces (FFP), Half Masks, and Full-Face Masks (for both respirators and BA).

- Key Requirement: A Face Fit Test is mandatory for all tight-fitting RPE to ensure the specific make, model, and size chosen forms a satisfactory seal with the individual wearer's face. Facial hair (even stubble) in the seal area is not permitted, as it will compromise the seal and the protection level.

2. Loose-fitting Facepieces

- Function: Do not rely on a tight seal. Protection is achieved by supplying enough clean air at a high flow rate (positive pressure) to the hood, helmet, or visor to create an out-flow barrier that prevents contaminants from entering.

- Examples: Hoods, Helmets, Visors, and Blouses (used with powered respirators or breathing apparatus).

- Benefit: These are an alternative for individuals who cannot be clean-shaven or cannot pass a face fit test.

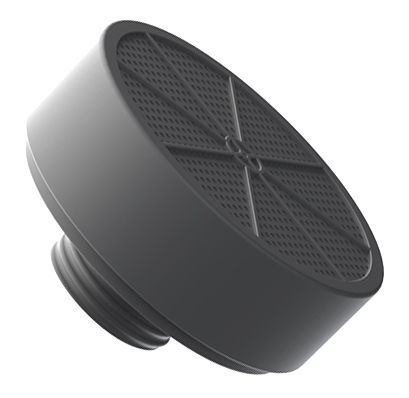

Mask Logic's IdealFIT 100 is a non-powered, half-mask respirator with a tight fitting facepiece

Assigned Protection Factor (APF)

The protection level provided by RPE is quantified by its Assigned Protection Factor (APF).

The APF is a numerical rating indicating the minimum level of protection an RPE item is expected to provide to the wearer, reducing the concentration of contaminants in the breathing zone. For example, an RPE with an APF of 20 must reduce the wearer's exposure by a factor of at least 20. This means the concentration of the hazardous substance inside the mask will be no more than 1/20th of the concentration in the ambient air.

| RPE Type (Example) | UK Standard | APF (HSE Guidance) |

|---|---|---|

| FFP2 (Disposable Half Mask) | EN 149 | 10 |

| FFP3 (Disposable Half Mask) | EN 149 | 20 |

| Reusable Half Mask (P3 filter) | EN 140 | 20 |

| Full Face Mask (P3 filter) | EN 136 | 40 |

| Powered Hood/Helmet (TH2P) | EN 12941 | 10 |

| Powered Hood/Helmet (TH3P) | EN 12941 | 40 |

| Breathing Apparatus (BA) | EN 12941 | 20 / 40 / 2000+ |

The selection of RPE requires comparing the required level of protection (based on the risk assessment and Workplace Exposure Limit, or WEL) against the APF of the equipment.

Filter types

Filtering RPE is classified by its filter type, which determines the specific hazards it protects against. The key to understanding this system in the UK is knowing the colour-coded letters used to mark the filters, standardised under the European norm EN 14387.

Particulate Filter Coding (EN 143)

Filters that protect against particles (dusts, mists, fumes, fibres, bacteria, and viruses) are known as particulate filters. They are always marked with the colour code White.

| Filter Class | Marking | Minimum Filtration Efficiency | Application |

|---|---|---|---|

| P1 | P1 (White) | 80% | Low efficiency, for non-toxic nuisance dust. |

| P2 | P2 (White) | 94% | Medium efficiency, for harmful solid and liquid aerosols (e.g., wood dust, concrete dust). |

| P3 | PS (White) | 99.95% | High efficiency, for highly toxic aerosols and carcinogenic substa99.95%nces (e.g., asbestos, silica, viruses). |

Reusable Filters

Particulate filters are also marked with:

- NR: Non-Reusable (single-shift use only, common on disposable FFP masks).

- R:

Reusable (can be used for more than one shift).

Gas and Vapour Filter Coding (EN 14387)

Gas and vapour filters use activated carbon or other sorbents to capture airborne chemical contaminants. They are categorised by a letter and a specific colour code, which must be clearly visible on the filter cartridge.

| Filter Type | Colour Code | Protects Against | Boiling Point |

|---|---|---|---|

| A | Brown | Organic gases and vapours (e.g., solvents, paint thinners). | >65°C |

| AX | Brown | Low-boiling organic compounds (e.g., acetone, methanol). | <65°C |

| B | Grey | Inorganic gases and vapours (e.g., chlorine, hydrogen sulphide, hydrogen cyanide). | N/A |

| E | Yellow | Acid gases and vapours (e.g., sulphur dioxide, hydrogen chloride). | N/A |

| K | Green | Ammonia and organic ammonia derivatives. | N/A |

| Hg-P3 | Red/White | Mercury vapour (must include a P3 particulate filter). | N/A |

| NO-P3 | Blue/White | Nitrous gases (e.g., nitrogen monoxide) (must include a P3 particulate filter). | N/A |

Filter Capacity Class (1, 2, or 3)

The letter code is followed by a number indicating the filter's capacity, which is related to its service life and the maximum concentration it can be used in.

- Class 1 (Low Capacity): For concentrations up to 1,000 ppm (0.1% by vol).

- Class 2 (Medium Capacity): For concentrations up to 5,000 ppm (0.5% by vol).

- Class 3 (High Capacity): For concentrations up to 10,000 ppm (1.0% by vol).

Example: An A2 filter protects against organic gases and vapours (BP > 65°C) at a medium capacity level.

Combined Filters

Many cartridges are Combined Filters, meaning they protect against both gases/vapours and particulates. The marking is a combination of the two codes.

Example: An A2P3 filter provides medium capacity protection against organic gases/vapours (BP > 65°C) and high efficiency protection against particulates. The physical filter will feature both the Brown and White colour codes.

Key Considerations for Gas and Combined Filters

- Filter Change Schedule: Unlike particulate filters (which become harder to breathe through as they clog), gas filters do not provide a clear indication of when they are saturated. A change schedule must be established by the employer, based on usage data and workplace concentrations, or the filter must be immediately replaced if the wearer detects a smell or taste of the contaminant.

- Single-Use Filters (AX): AX filters (low-boiling organic compounds) and CO filters are typically single-shift or single-use only and cannot be reused, even if they have capacity remaining.

Mandatory Face Fit Testing

The requirement for face fit testing in the UK is a core legal duty derived primarily from the Control of Substances Hazardous to Health (COSHH) Regulations 2002 and enforced by the Health and Safety Executive (HSE).

The HSE is very clear that RPE cannot protect the wearer if it leaks, and a major cause of leaks is poor fit.

The Approved Codes of Practice (ACOP) supporting the COSHH Regulations and other specific regulations (like the Control of Asbestos Regulations) make fit testing a legal requirement in the following circumstances:

1. For All Tight-Fitting RPE

Fit testing is mandatory for any RPE device that relies on a tight seal to the wearer's face to function correctly.

This includes:

- All Filtering Facepieces (FFP1, FFP2, FFP3): These are the disposable, single-use masks.

- Reusable Half Masks: Those with replaceable filters (gas/vapour and/or particulate).

- Full-Face Masks: Used with respirators or breathing apparatus (BA).

- Tight-Fitting Powered and Airline RPE: Even though these operate under positive pressure, a fit test is still required because inward leakage can still occur during heavy exertion.

2. Before First Use

A face fit test must be conducted as part of the initial selection process before a worker uses any tight-fitting RPE for the first time in a hazardous environment.

3. When the RPE Model Changes

A re-test is required immediately if there is a change in the RPE supplied to the wearer, specifically a change in the type, make, model, or size of the facepiece.

4. When the Wearer's Face Changes

A re-test is mandatory whenever a change occurs to the wearer that could affect the face seal. This includes, but is not limited to:

- Significant weight loss or gain.

- Substantial dental work (e.g., extractions or new dentures).

- Facial scarring, surgery, or cosmetic changes in the face seal area.

The Clean-Shaven Rule

A key part of the HSE's guidance is the requirement for wearers of tight-fitting RPE to be clean-shaven in the area where the mask seals to the face. Even light stubble can compromise the seal, allowing contaminated air to bypass the filter.

If a worker cannot be clean-shaven (e.g., for religious reasons), the employer is required to provide an alternative type of RPE that does not rely on a tight face seal, such as a loose-fitting powered respirator with a hood or helmet.

When Fit Testing is Not Required

Face fit testing is

not required for RPE that does not rely on a tight face seal. This primarily covers:

- Loose-Fitting Powered Respirators: Units with hoods, helmets, or visors (e.g., TH2 or TH3 rated units).

- Loose-Fitting Air-Fed Hoods/Helmets: Used with airline breathing apparatus.

These devices are designed to provide protection through a continuous flow of air that creates a positive pressure barrier, pushing air out of the hood rather than relying on a tight seal.

Repeat Testing (Good Practice)

While the HSE does not mandate a fixed maximum time interval for repeat fit testing, it is considered good practice to re-test regularly.

Many organisations follow the recommendation of the

Fit2Fit accreditation scheme (supported by the HSE) to repeat the fit test at a suitable interval, often

every two years, as part of a comprehensive RPE programme. More frequent testing may be advisable where RPE is the primary control measure.